Which One Is Suitable For Mine Ventilation: Flexible Ventilation Duct Or Rigid Duct?

Mining is a complex and dangerous job, and you can never be too cautious about ventilation systems. A good ventilation system can discharge industrial waste gas in time, thus ensuring the safety of workers. It is necessary to choose a suitable ventilation duct. Today, we will compare the flexible ventilation duct and rigid air duct, who is more suitable for mine ventilation?

Advantages of flexible ventilation ducts

Flexibility: The flexible pipe has extremely high flexibility, which can be bent and twisted to adapt to the complex terrain and roadway structure of the mine. This makes it easier bypass obstacles, reducing installation difficulty and cost.

Portability: Compared with rigid air ducts, flexible ventilation ducts are lighter in weight and easy to handle and install. In the mine environment, this is particularly important because it can reduce the labor cost and improve work efficiency.

Wear resistance: The surface of the flexible air duct is coated with PVC, which can resist friction and wear and extend the service life.

Cost effectiveness: Due to the particularity of its manufacturing materials and processes, flexible air ducts may have certain advantages in cost, especially in the case of frequent replacement or adjustment of ventilation ducts.

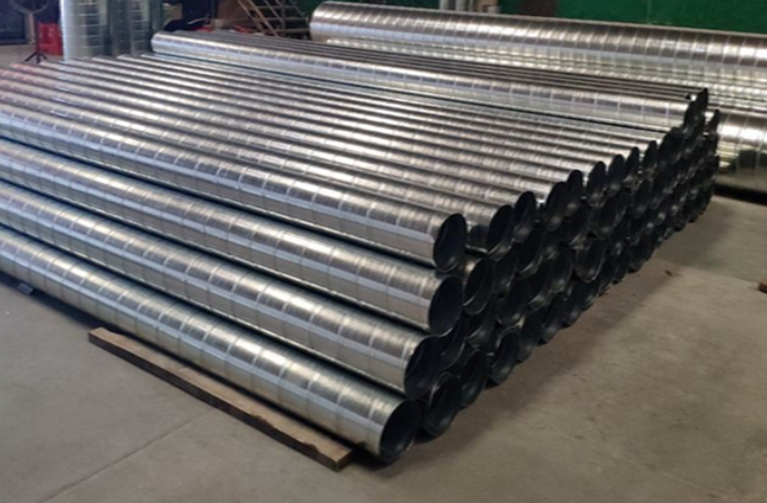

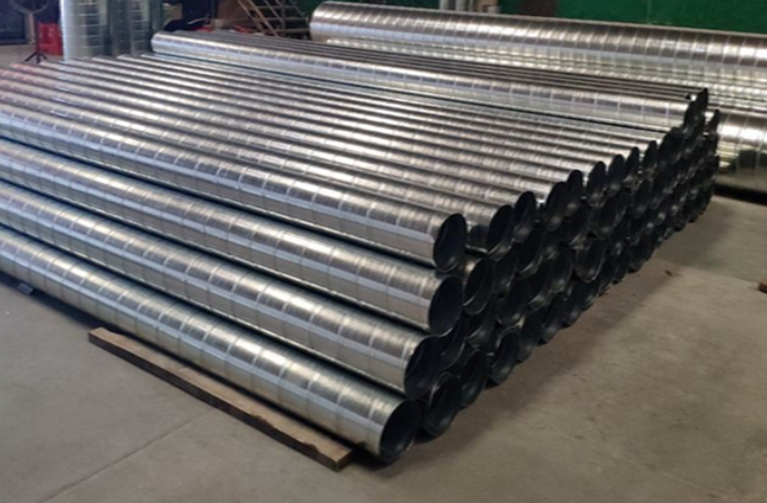

Advantages of rigid ducts

Stability: Rigid ducts can provide better stability due to their strong structure. Stability is essential to ensure effective ventilation

Tightness: The connection between rigid ducts is usually tighter, which can provide better sealing and reduce air leakage. This is of great significance for improving the ventilation efficiency.

Pressure capacity: In some cases that need to withstand large wind pressure or negative pressure, rigid ducts may be more advantageous. However, this requirement may not be prominent in most mine ventilation systems.

Conclusion

In mine ventilation system, flexible ventilation duct and rigid air duct have their own advantages. In general, flexible ventilation duct is more suitable for mines, complex terrain, or situations where ventilation ducts need to be adjusted frequently. The rigid air duct is more suitable for occasions with higher requirements for stability, sealing and pressure capacity.

However, it should be noted that the choice of which air duct needs to be considered according to the actual situation. For example, the size of the mine, tunnel structure, ventilation needs, maintenance costs and other factors may affect the final choice.